Felwag: Insight into precision work

NEUGEROUS PUBLIC Not all rims are the same - at the open day of the rim specialist, Felwag AG in Worb BE, numerous visitors learned about the science behind it. For many car owners, a car is only really beautiful when it rolls on perfect wheels. And if the rims show a scratch or other damage, [...]

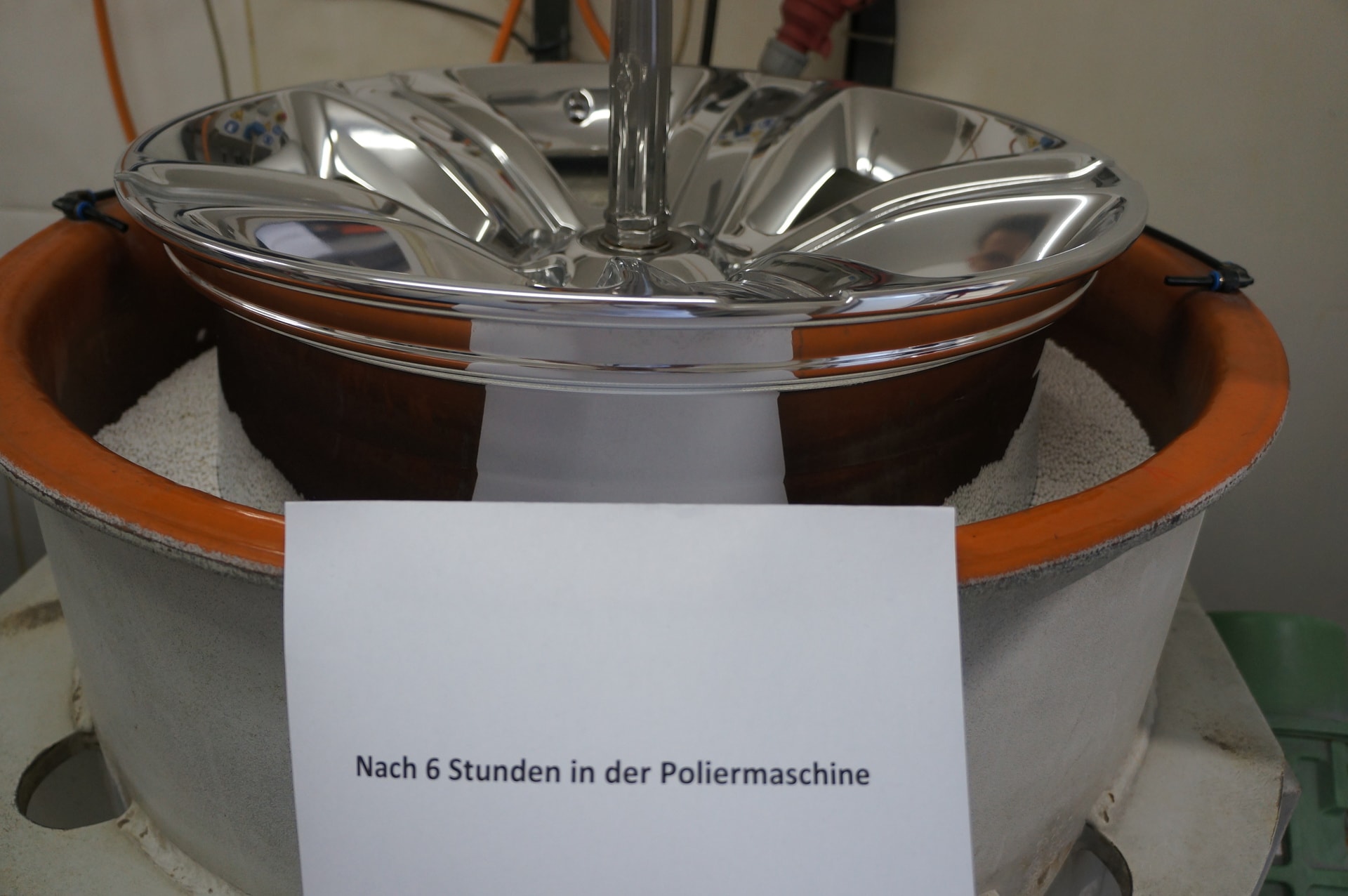

For many car owners, a car is only really beautiful when it rolls on perfect wheels. And if the rims have a scratch or other damage, for some this is just as bad as a dent in the bodywork.

Programs for each type of rim

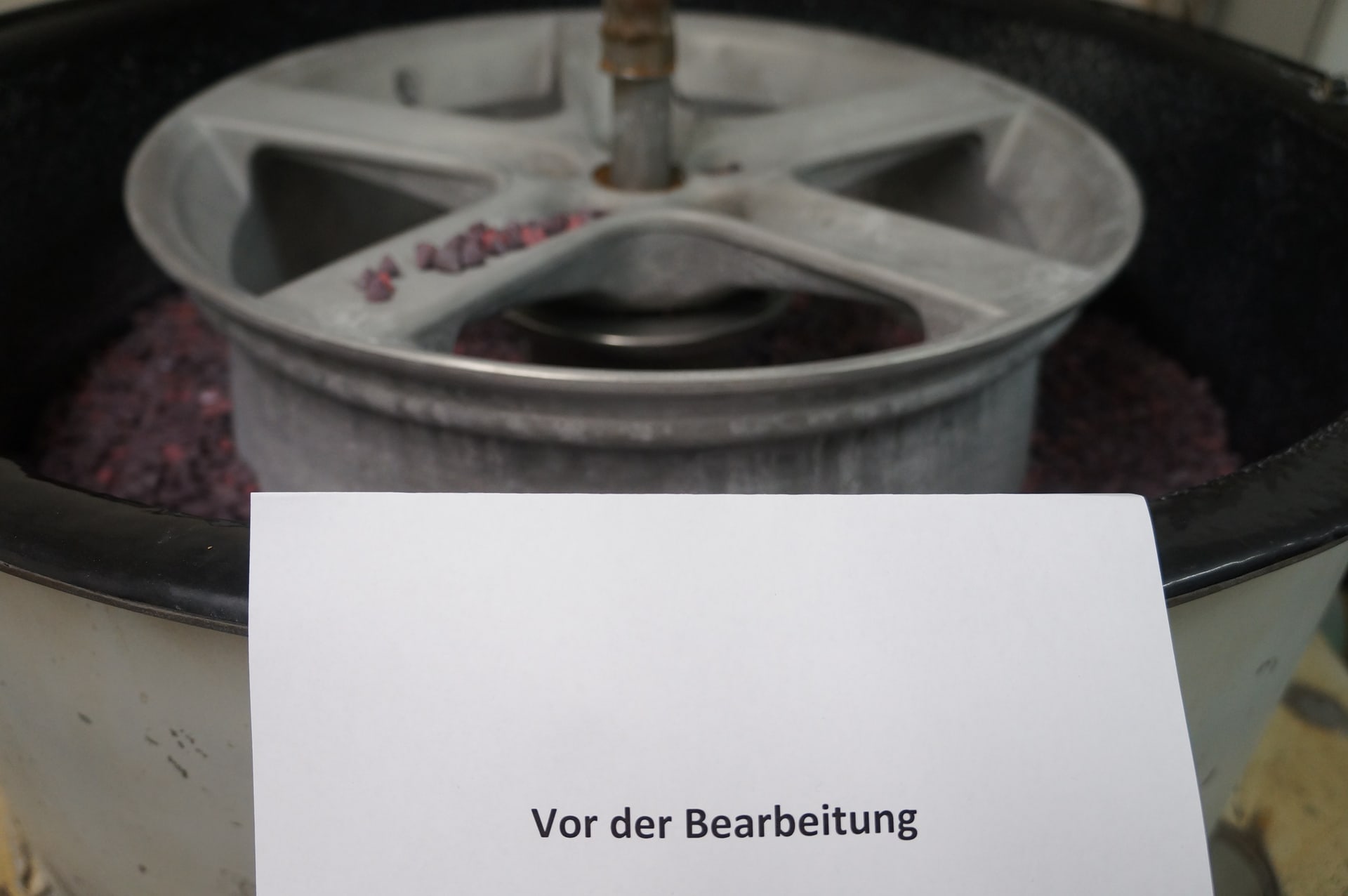

Felwag AG, based in Worb just outside Berne, knows how to deal with such matters and provides a quick remedy. Their main activity is the repair and refinement of rims of any origin.

André Dürig, Managing Director: "We have around 2000 programs for every type of rim stored in our computer. And if we don't have one, we write it."

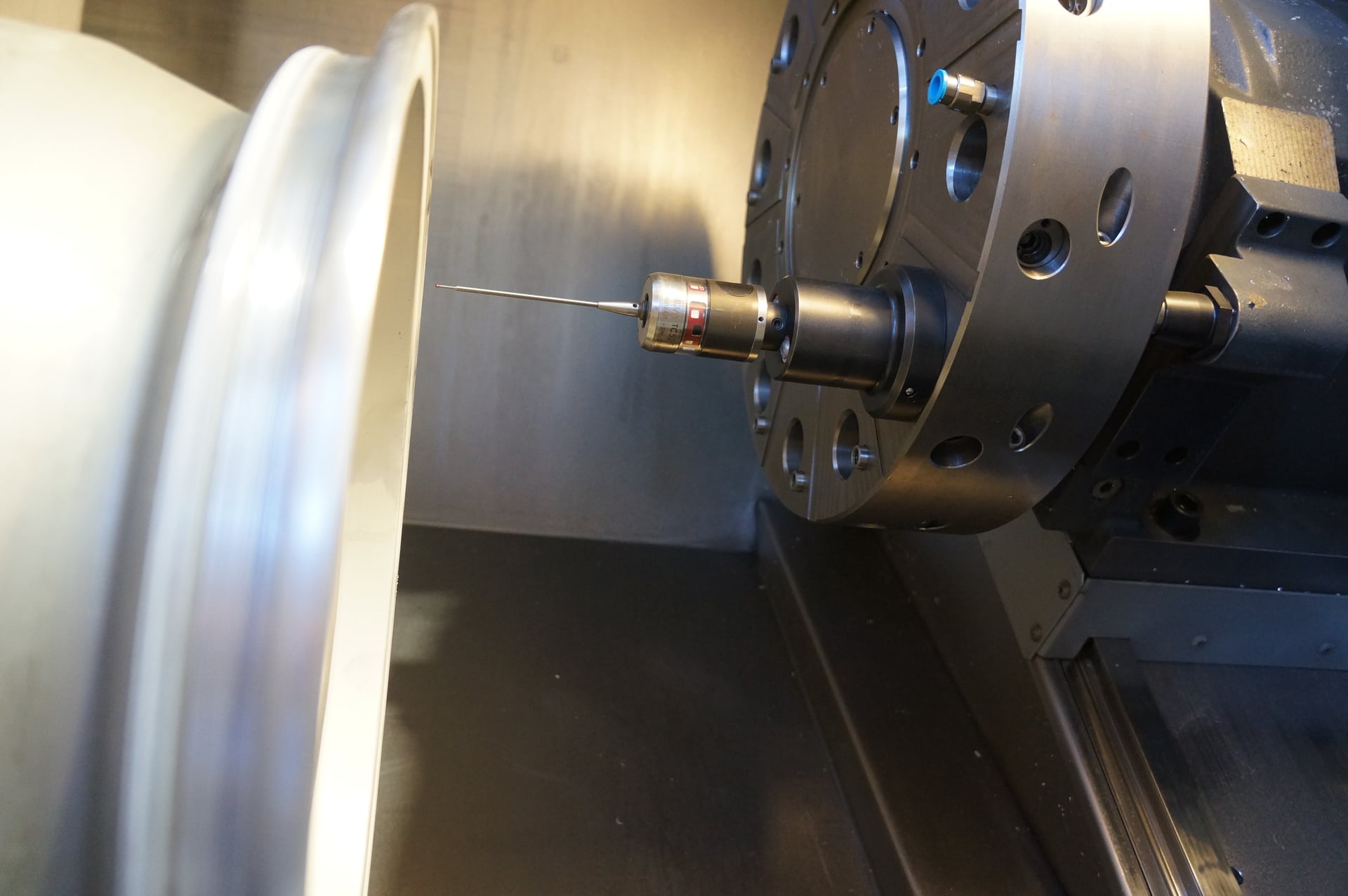

Machining is a science

At the open day at Industriestrasse 25 in Worb, visitors - customers or simply interested parties - were able to find out about the individual machining steps. And everyone was amazed to discover that rim machining is a science that requires a great deal of know-how and the appropriate infrastructure.

Both are available at Felwag AG, which also resulted in an extension. On this occasion, the company, which has been in existence since 2008, also caught up on its 10-year anniversary.

Prices in each case by arrangement

Up to 100 rims are processed per day. The costs for a repair or refinement, also from complete wheel, amount from 200 to 400 francs per piece, whereby it can go in special cases up to 1000 francs. However, the price is always defined and offered beforehand.

... Formula 1 also sends its regards

Some of it is manual work, but most of it is entrusted to state-of-the-art machines. The inventory also includes high-precision CNC machines from Haas. Company owner Gene Haas has been running his own Formula 1 team for years and also plans to visit his automotive-savvy Swiss customer in the foreseeable future. André Dürig has a good name in Swiss slalom and hillclimb racing as a driver and event sponsor himself.

22 employees for a wide clientele

Felwag AG employs 22 people. Its own 24-hour delivery service collects the rims from corporate customers and returns them repaired and refreshed as if they were brand new. Private customers currently have access to nine bases throughout Switzerland and in Schaan (FL). They will be happy to accept the rims there.

The clientele also includes teams and drivers from all over Switzerland. For a restored Mazda Group C, as it once raced in Le Mans, Felwag AG recently made special racing rims according to a template. In addition, Emil Frey Classics entrusts the rims of its classic vehicles to the specialized Bernese company.