Automotive industry: Recycling is a must

Sustainability is key, even in car manufacturing. Alternative materials and recycled materials are playing an increasingly important role in production. This is particularly evident in the interior, but sustainable innovations are even more significant in body construction.

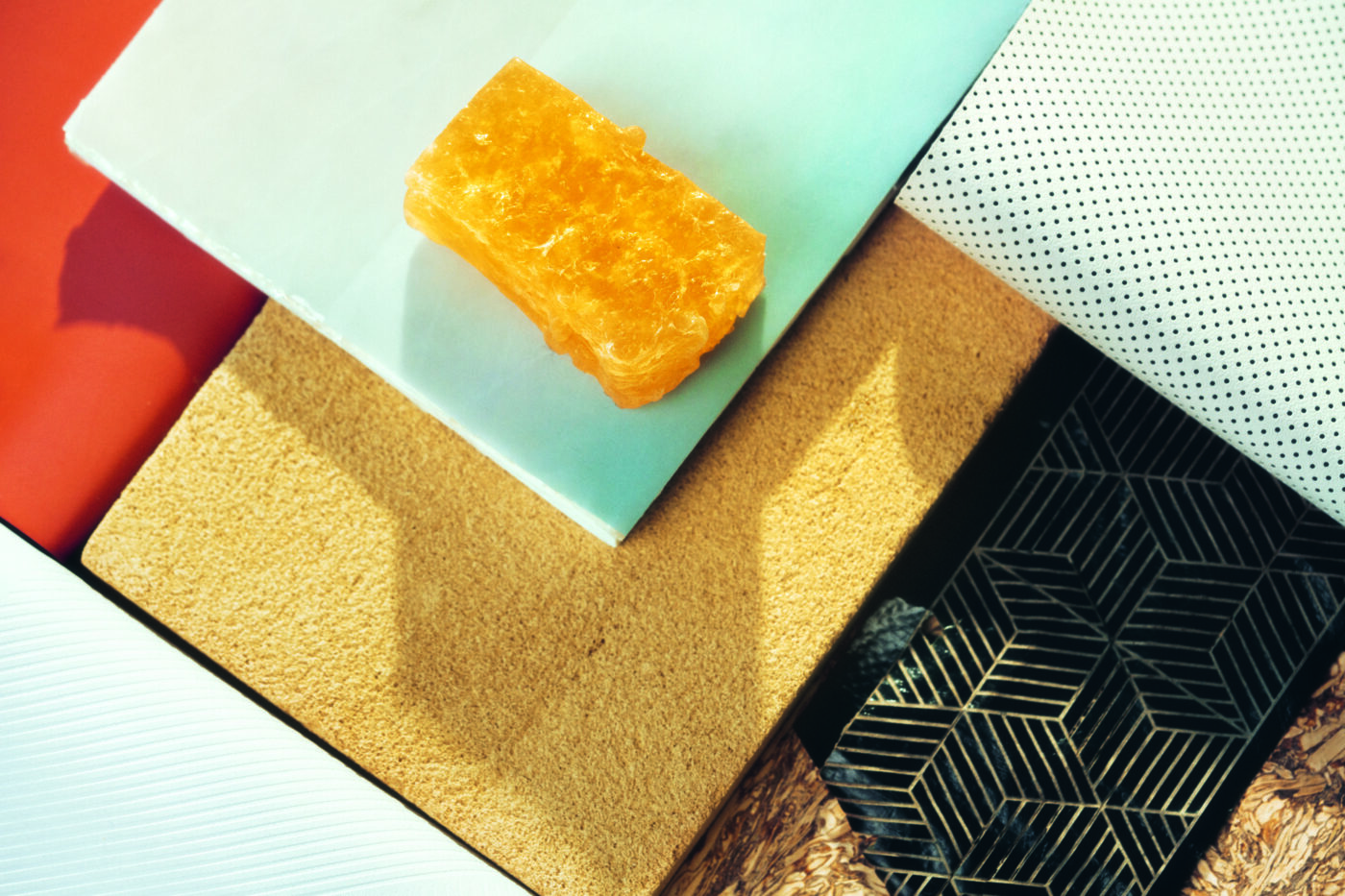

The interior of a car largely determines the characteristic brand experience. Particular attention must therefore be paid to visual and tactile quality. Dashboard and door trim made from fiber-reinforced natural materials or sustainable leather substitutes are particularly popular in modern automotive engineering today. Mercedes, Mini, BMW, and Jaguar are using sustainably produced and processed leather in their first models and emphasize that this takes into account everything from animal husbandry to the tanning process. In addition, various upholstery fabrics are offered that consist of up to 100 percent recycled PET bottles. The floor coverings in the Mercedes EQS use a nylon yarn made from discarded carpets and fishing nets.

In many new cars today, cup holders and decorative covers are made from recycled materials based on renewable raw materials. Such recycled materials often meet the same quality requirements as primary materials. Audi and Cupra, for example, manufacture seat upholstery using fibers from waste PET bottles, and many major car manufacturers use thermoplastics reinforced with hemp, sisal, flax, banana, or kenaf fibers for door panels and other trim.

More secondary material

Car manufacturers increasingly see end-of-life vehicles as sources of raw materials for the production of new models. Audi states that no less than 95 percent of a car can be recycled and reused. Of course, this requires the vehicle to be designed with recycling in mind. Sustainability is thus becoming an increasingly integral part of the entire production process. Instead of primary raw materials, as much recycled material as possible should be used. In order to increase the proportion of secondary raw materials in new vehicles and thus reduce resource consumption, manufacturers are working to close material cycles and further improve the efficiency of production processes. Even during the development of a vehicle, concepts are created with which all components and materials can be checked for their suitability for reuse.

Since the numerous types of plastic cannot currently be separated at reasonable cost and in sufficient quality, their reuse is in most cases accompanied by downcycling. This means that the recycled material can only be used for components that have to meet lower quality requirements. There are still no suitable processing methods for carbon fiber-reinforced plastics, which are increasingly being used in structural components in more expensive vehicles. Carbon fibers cannot be separated and recycled using conventional methods.

Heavyweight metals

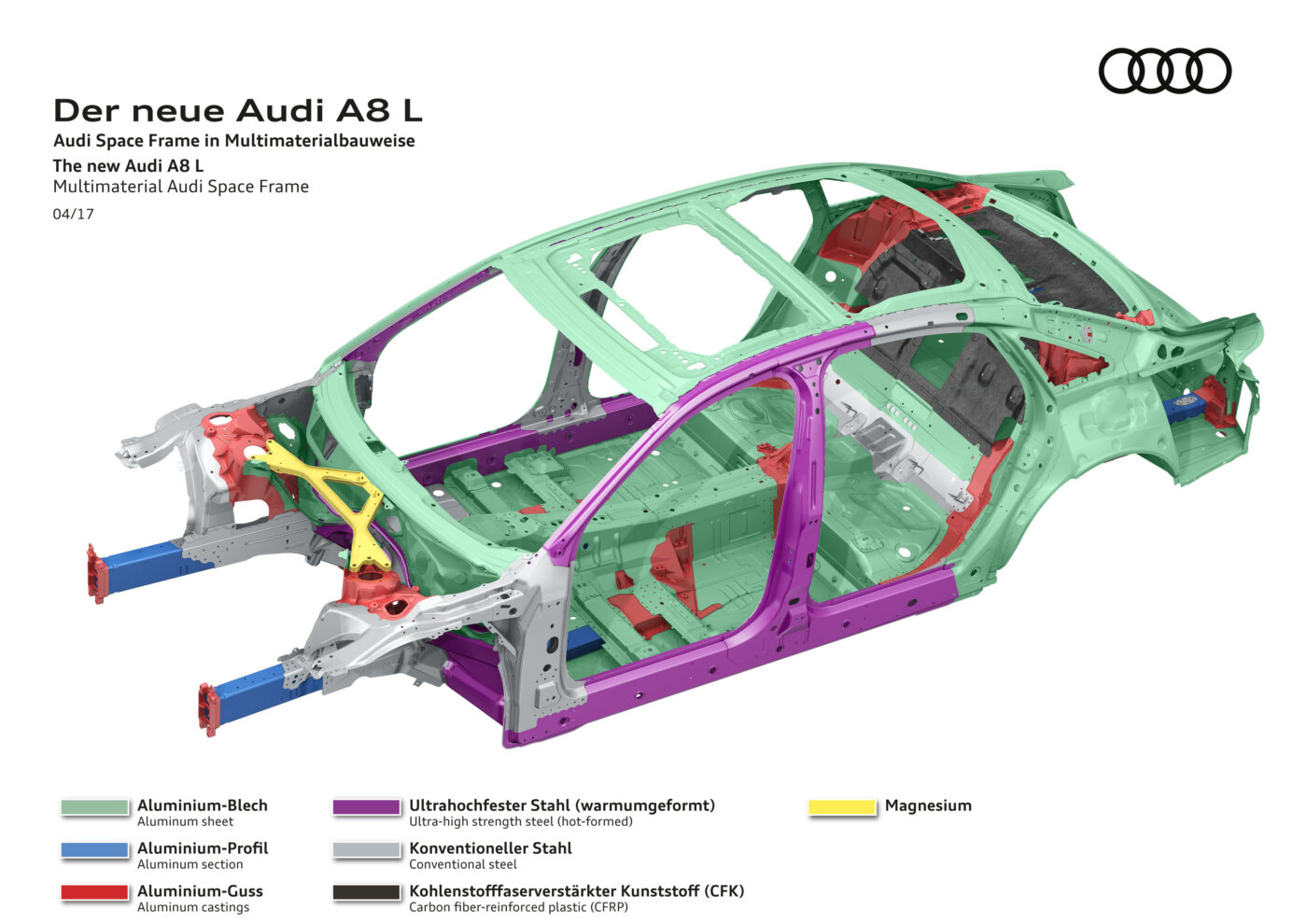

In addition to the vehicle interior, the sustainability assessment of the materials used in cars also includes, above all, the body and shell. Steel and aluminum are mostly used in these areas—materials that are particularly CO₂-intensive to manufacture. Conventional primary steel production generates more than two tons of CO₂ per ton of steel. However, by using a new production process instead of the familiar coke-based blast furnace production, steel production can become almost CO₂-free. In the so-called direct reduction process, the supplier uses hydrogen and electricity from 100 percent renewable energy sources instead of coking coal for steel production.

Metals account for 70 to 75 percent of the weight of a modern car. Since they are relatively easy to recycle, around 98 percent can be recovered and reused as raw material. Recycling steel requires 60 to 75 percent less energy than primary production, which makes a significant contribution to sustainability.

Single-variety aluminum recycling

Although aluminum requires more energy than steel to produce from bauxite, it is much less demanding to recycle. The energy used in the primary production of aluminum is therefore retained in the material. When recycled separately, there is no loss of metal quality. However, recycling mixed aluminum materials inevitably involves downcycling. Furthermore, a conventional mid-range car contains around 25 kilograms of copper, while an electric car contains more than 70 kilograms. On the positive side, thanks to careful recycling of end-of-life vehicles, almost half of today's copper demand is met by recycled material.

Special case: electric cars

The growing sales figures for electric cars go hand in hand with rising demand for raw materials for batteries and electric motors. Energy storage devices require large quantities of mineral raw materials, some of which are mined and marketed under socially and geologically problematic conditions. It is therefore important that these materials are recycled at the end of a car's life.

Battery recycling in its infancy

In addition to traditional materials, many additional materials are required for energy storage and the propulsion of electric cars. Lithium, nickel, cobalt, manganese, and graphite play important roles in batteries, while copper and rare earths are used in electric motors. Although these raw materials are not scarce from a geological perspective, temporary supply bottlenecks can still occur. It is certain that material prices will continue to account for a significant portion of battery costs. For this reason alone, reuse is important. Many companies and research institutes are currently testing the recycling of various e-components. It can be assumed that their disposal will not be a problem, even if larger quantities will have to be processed in a few years' time and the recycling of drive batteries is still in its infancy.

Recycling rates are rising steadily

The basic plan is that the electric car's lithium-ion battery pack, which will still be powerful after eight to ten years of operation, will be removed and continue to be used as a stationary energy storage device, thus beginning its «second life.» If this is not possible, the batteries will be dismantled so that the raw materials can be reused. The relevant processes have already been tested. And for many other parts, science and the automotive industry will soon develop solutions that contribute to sustainability. Politicians are demanding that new vehicles be designed in such a way that components can be easily removed and reused, and have recently increased the recycling quotas for plastics once again.